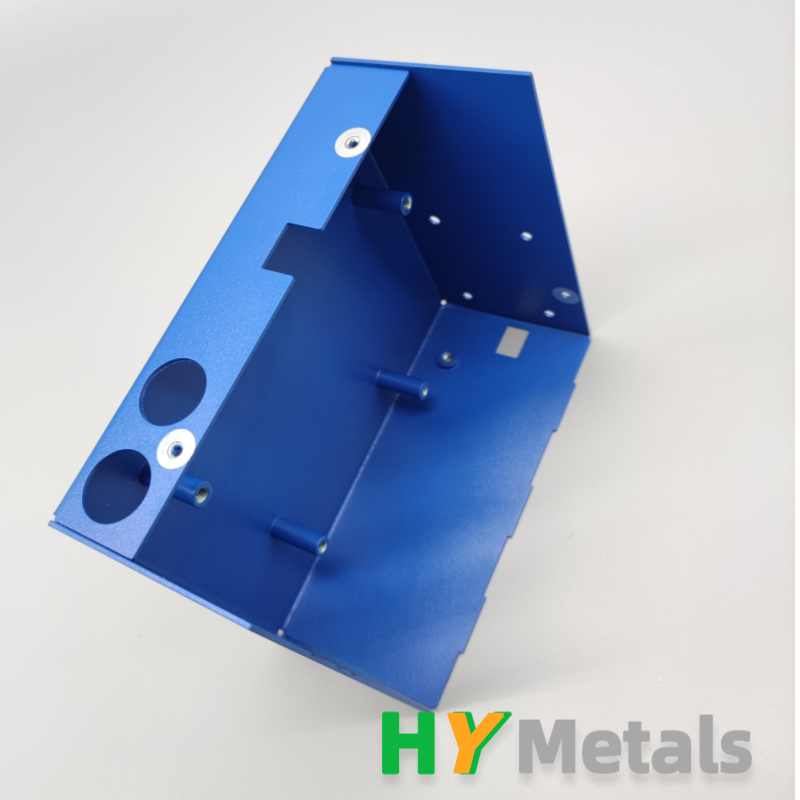

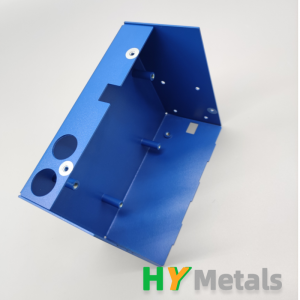

Qaybaha birta ah ee la habeeyey oo aan u baahnayn dahaar meelo cayiman

Sharaxaada

| Magaca Qaybta | Qaybaha birta gaarka ah oo leh daahan |

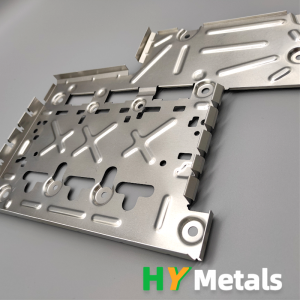

| Halbeegga ama Habboon | Qaybaha birta ah ee xaashida ah ee la habeeyey iyo qaybaha mashiinka CNC |

| Cabbirka | Sida ku cad sawirada |

| Dulqaad | Marka loo eego shuruudahaaga, marka la dalbado |

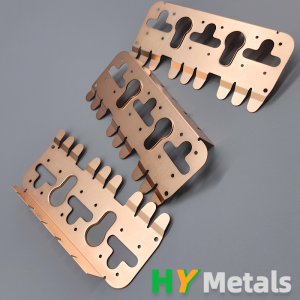

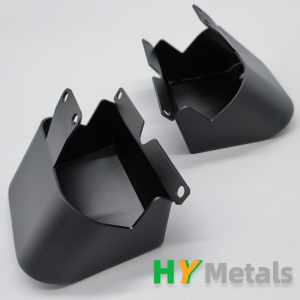

| Qalab | Aluminium, bir, bir aan lahayn, naxaas, naxaas |

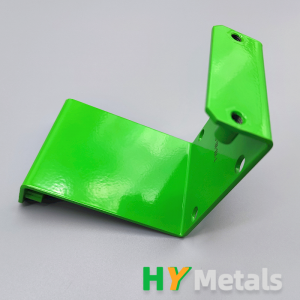

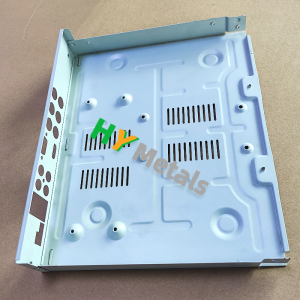

| Dusha sare ayaa dhammaatay | Dahaarka budada, dajinta, anodizing |

| Codsiga | Wixii kala duwan ee warshadaha |

| Habka | Mashiinka CNC, samaynta biraha xaashida |

Sida loola tacaalo Shuruudaha dahaarka ma laha meel cayiman oo loogu talagalay qaybaha birta

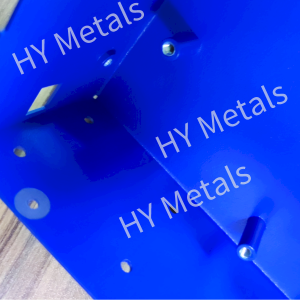

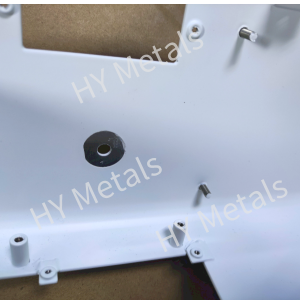

Marka ay timaado qaybaha birta, dahaarka waxay u adeegaan dhowr ujeedo oo muhiim ah. Waxay wanaajisaa muuqaalka qaybaha, waxay ka ilaalisaa walxaha dibadda sida daxalka iyo xirashada, waxayna kordhisaa noloshooda adeegga. Caadi ahaan, qaybaha birta ah waa budo dahaar ah, anodized ama dhejis ah. Si kastaba ha ahaatee, qaar ka mid ah biraha xaashida ah ama qaybaha mashiinada CNC ayaa laga yaabaa inay u baahdaan dhammaan dusha sare in la dahaadho marka laga reebo meelahaas marka korantada looga baahan yahay meelaha gaarka ah ee qaybta.

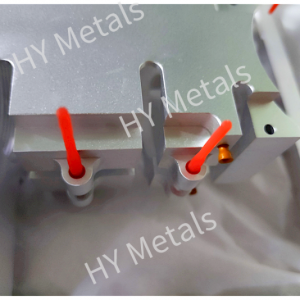

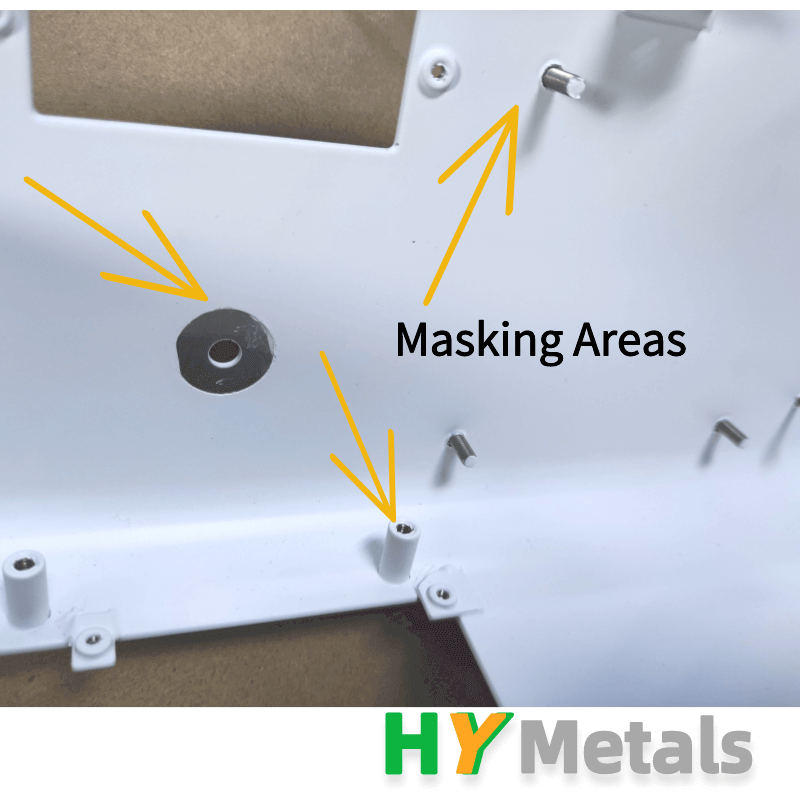

Xaaladdan oo kale, waa lagama maarmaan in la daboolo meelaha aan u baahnayn daahan. Maaskarada ayaa loo baahan yahay in si taxadar leh loo sameeyo si loo hubiyo in meelaha la daboolay ay ka xor yihiin rinjiga iyo in meelaha soo haray ay yihiin kuwo si fiican loo dahaadhay. Waa kuwan qaar ka mid ah talooyinka lagu hubinayo in habka dahaarka uu si habsami leh u socdo.

Maaskarada rinjiga

Marka dahaarka budada ah, ku daboolida aagga cajalado ayaa ah habka ugu habboon ee lagu ilaalin karo meelaha aan rinji lahayn. Marka hore, dusha sare wuxuu u baahan yahay in si habboon loo nadiifiyo ka dibna lagu daboolo cajalad ama filim kasta oo heerkulbeeg ah oo u adkeysan kara heerkulka sare. Dahaarka ka dib, cajaladda waxay u baahan tahay in si taxadar leh loo saaro si aysan dahaarka u soo bixin. Maaskarada habka daahan budada ah waxay u baahan tahay sax si loo hagaajiyo tayada alaabta ugu dambeysa.

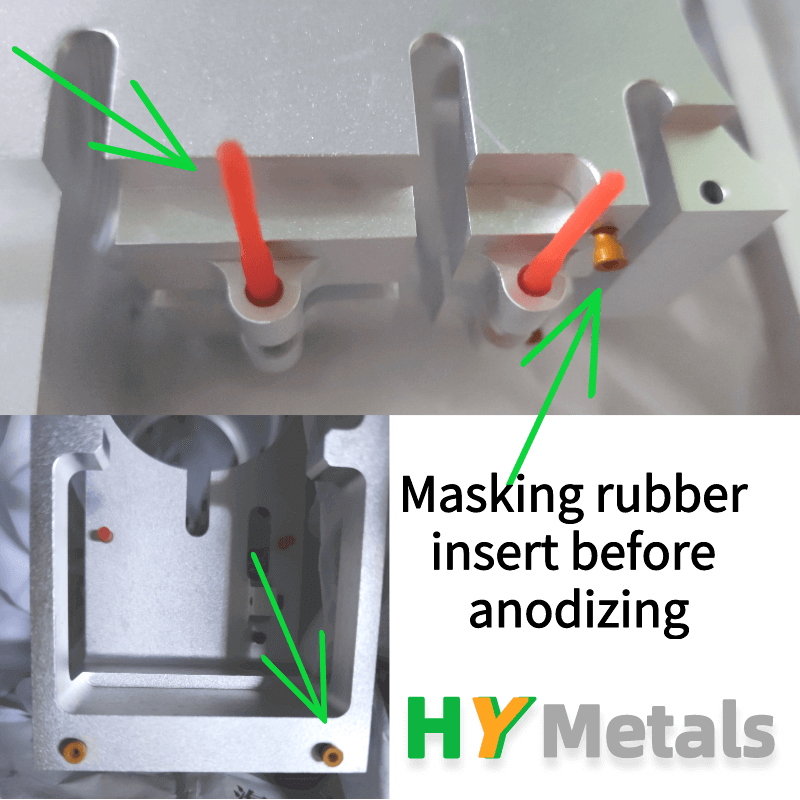

Anodizing and Plating

Inta lagu jiro habka anodizing qaybaha aluminium, lakabka oksaydh ayaa lagu sameeyay dusha birta oo kor u qaadaysa muuqaalka iyada oo sidoo kale bixisa iska caabbinta daxalka. Sidoo kale, isticmaal xabagta-anti-oxidant si aad u ilaaliso qaybta inta lagu jiro habka waji-xidhka. Qaybaha aluminiumka anodized waxaa lagu qarin karaa maaskaro iyadoo la isticmaalayo xabagta sida nitrocellulose ama rinjiga.

Marka la dhejiyo qaybaha birta, waxaa lagama maarmaan ah in la daboolo dunta nuts ama dhejiska si looga fogaado daboolka. Isticmaalka galinta caaggu waxay xal kale u noqonaysaa godadka, taas oo u oggolaanaysa dunta inay ka baxsadaan habka daminta.

Qaybaha biraha gaarka ah

Marka la soo saarayo qaybo bir ah oo khaas ah, waxaa muhiim ah in la hubiyo in qaybaha ay buuxiyaan shuruudaha saxda ah ee macaamilka. Farsamooyinka waji-xidhka saxda ah ayaa muhiim u ah biraha birta ah iyo qaybaha mashiinada CNC ee aan u baahnayn dahaadh meelo gaar ah. Dahaarka saxda ah ee injineernimada macneheedu waa u fiirsashada faahfaahinta adag iyo tayada alaabta la isticmaalo. Ka dib oo dhan, khaladaadka dahaarka waxay u horseedi karaan qaybo lumay iyo kharashyo dheeraad ah oo lama filaan ah.

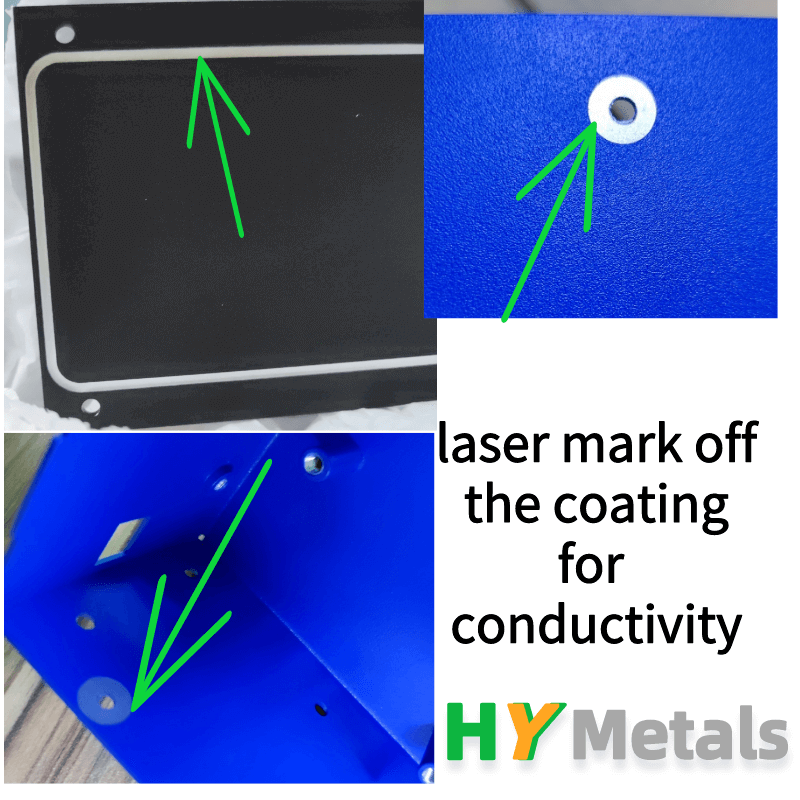

rinjiyeynta calaamadaynta leysarka

Alaab kasta oo lagu calaamadin karo laysarka waxay bixisaa faa'iidooyin la taaban karo marka la dahaadho. Calaamadeynta laser-ka waa hab aad u fiican oo looga saaro daaha inta lagu jiro kulanka, inta badan ka dib marka la qariyo meelaha. Habkan calaamadaynta ayaa ka tagaya sawir madow oo madow oo ku yaal qaybta birta oo u muuqata mid wanaagsan oo ka soo horjeeda agagaarka agagaarka.

Marka la soo koobo, waji-xidhashadu waa lama huraan marka la dahaadho qaybaha birta ah ee caadiga ah ee aan lahayn shuruudaha dahaarka ee meelaha loo qoondeeyay. Haddii aad isticmaalayso anodizing, electroplating ama daahan budada ah, alaabooyinka kala duwan waxay u baahan yihiin farsamooyin waji-xidhid gaar ah si loo hubiyo tayada alaabta ugu dambeysa. U hubso inaad si taxadar leh u qaadato taxadarka waji-xidhka ka hor intaadan sii wadin habka daaha.